Industrial processors use comminution methods to transform raw materials into usable products. It means turning big, solid pieces into smaller, specialized particles. After primary crushing, grinding steps help refine particles until they meet processing requirements. High-capacity ball mills help achieve this task. These systems follow crushers to break materials into fine powder while meeting processing requirements.

A purchased one will make your entire post-crushing process run more productively. A high-capacity mill delivers reliable grinding results to bulk materials. The type of mill you choose directly affects how much energy you use and determines your production results. Since 1985, Eastman Technology has developed effective and reliable grinding systems tailored to meet industry requirements. Over many years of supplying ball mill for sale or processing equipment, Eastman Technology gained worldwide recognition as a leader in its field.

Exploring the Importance of Ball Mills in Industrial Production Systems

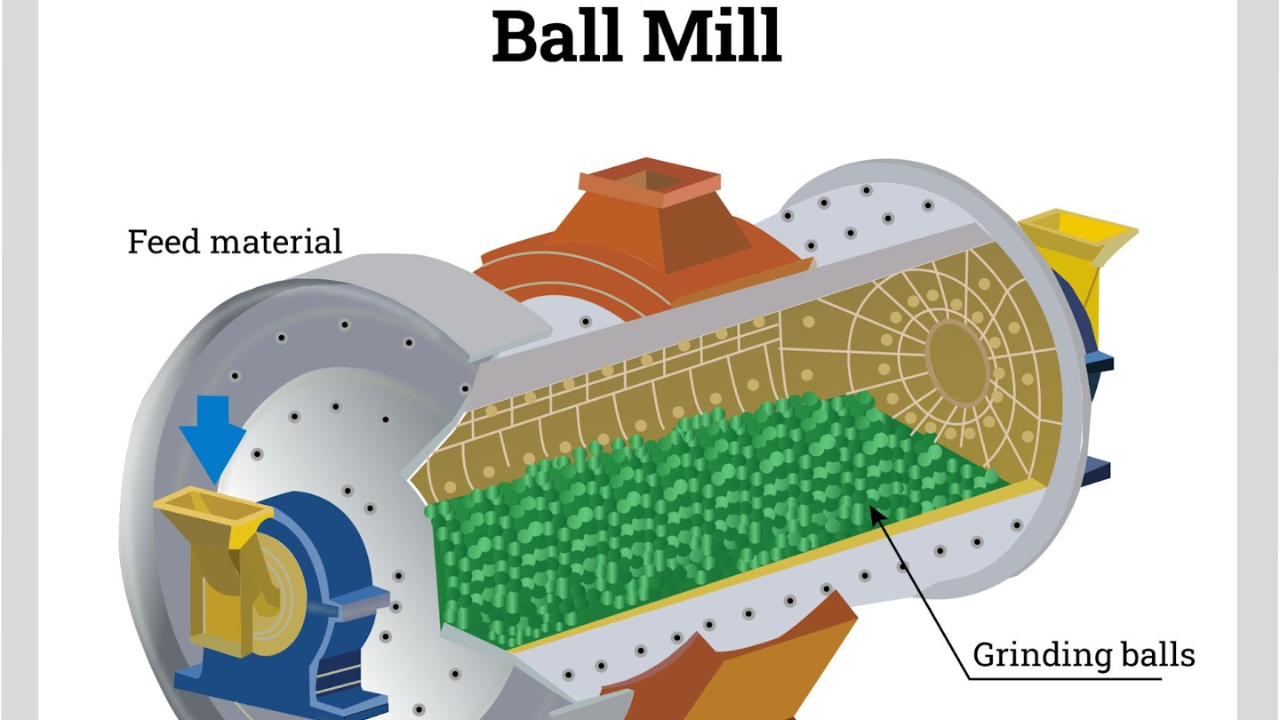

The primary function of it is to grind materials rather than to crush them. After crushing, the material still needs further processing to reach its final form. It transforms particles into a state ready for applications or fine powder generation. Grinding media inside a spinning cylinder applies impact and friction effects to process materials as designed.

They operate extensively across different industries, including mineral processing for ore concentration and cement production, as well as ceramic and metal production. A standard production line starts with a crusher and adds either a SAG to reach the required particle size. These mills transform raw, crushed materials into refined powder products while meeting the requirements between the initial feed and the ultimate output.

Key Features of High-Capacity Ball Mills

These mills from Eastman work well in different size ranges and production levels. They come in sizes Ø900×1800mm to Ø3200×4500mm to handle production rates from 1 TPH to 95 TPH. You can choose production sizes to meet demands without losing operational effectiveness. These mills handle input sizes of 25 mm or less and create multiple particle sizes to meet different application requirements.

The mills maintain uninterrupted operations thanks to built-in feeding and discharging mechanisms. This setup lets grinding continue without stopping operations. During spinning, the mill shell draws grinding media upward and downward in a controlled motion, which produces multiple impact events. The motion increases grinding strength and creates a consistent output particle size in every production cycle.

Material Compatibility and Application Scope

The Eastman ball mills work with many materials like quartz, limestone, coal, feldspar, and iron ores. These mills work with both wet and dry grinding processes simultaneously. These machines modify their operations to match material requirements within both the energy production and ceramics industries. Different materials respond differently to chemicals when you grind them into an amorphous form or conduct solid-state reactions.

Mining industries use these mills to produce pigments and extract metals successfully. They create dependable results both for getting minerals out and making high-quality powders for different applications.

Efficiency Factors: Grinding Media and Milling Parameters

Choosing the right grinding media improves the results of your milling work. The best grinding media depends on how large it is, along with its material makeup, density, hardness, and chemistry. Media made of tungsten carbide or zirconia provides superior grinding performance and produces more regular, tiny particles. You can prevent product pollution during the milling process when you pick the right grinding media for your raw materials.

Milling techniques that step through several types of grinding media produce finer final particles than single-step methods. This method produces a focused particle range and cuts down on processing inconsistencies. Investing in high-density media leads to more extended equipment durability, which saves money over time.

Advantages of Choosing Eastman High-Capacity Ball Mills

Eastman creates ball mills built for demanding industrial processes. The mills handle demanding tasks without needing frequent repairs, so they serve your equipment longer. Eastman’s modular system makes it simple to merge their mills into both small plant setups and full-scale processing centers.

Studies confirm these mills improve chemical reactions and decrease power usage through their tested results. Your process benefits from steady operations that produce consistent results and require minimal upkeep. Every process improvement helps companies work better and spend less money throughout their operations.

Operational Insights: How Eastman Ball Mills Work

Eastman mills work when you put grinding media into a rotating cylindrical shell. The device takes in material from a 60-degree cone feeder and releases it from a 30-degree cone exit. While the rotating shell turns, the media moves up and down in steps to grind the components inside.

The continuous movement of the machine parts creates effective contact between the materials and grinding media. The repeated collision and rubbing of materials while moving down helps create a precise and uniform grinding result. The grinding performance depends on how fast the shell spins because steady turning distributes power better than random motions.

Conclusion

Ball mills handle large amounts of crushed material to produce final fine products. These machines simplify grinding tasks while delivering precise results that today’s industrial processes need. The range of Eastman mills covers many sizes and provides durable performance that keeps every unit working effectively.

Working with Eastman to enhance your grinding capacity will bring you lasting operational success. The right production equipment helps you improve your processes at lower costs while staying competitive in your market.