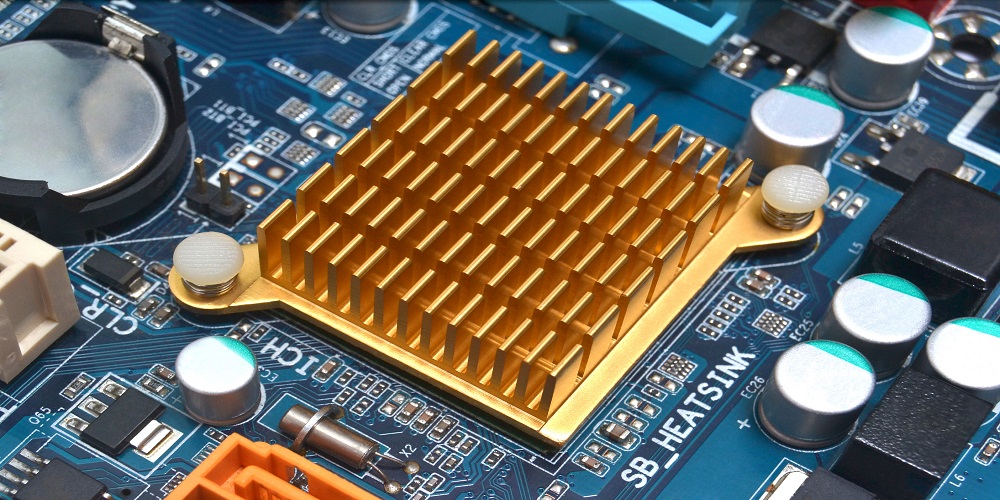

Aluminum expulsion heat sinks are an extraordinary decision for fundamental intensity the board purposes for a few reasons. Aluminum is a lightweight material, which makes it simple to work with and introduce. This can be a benefit in fundamental applications where weight is a worry. Aluminum expulsion heat sinks can be handily modified to fit the particular prerequisites of your application, including different blade shapes, sizes, and surface treatments. Aluminum is an exceptionally conductive, implying that it can rapidly and successfully move heat away from electronic parts. This makes aluminum expulsion heat sinks ideal for scattering heat in fundamental applications. The heatsink material selection is also an important thing.

Why aluminum extrusion heat sink is important for economic and decorative processes?

The outer layer of aluminum expulsion heat sinks can be done in various tones and surfaces, which can be significant for applications where the feel is significant. The improving completion can make the intensity sink all the more outwardly engaging and assist it with mixing in with the encompassing parts. Aluminum expulsion is a practical assembling process, implying that intensity sinks produced using aluminum expulsion will generally be more affordable than different sorts of intensity sinks. This can settle on them a more prudent decision for heat the board applications. aluminum expulsion heat sinks are both monetarily and gorgeously significant because of their expense viability, warm conductivity, adaptability, and capacity to be done in an ornamental way.

Strong comprehensive mechanical properties of aluminum extrusion heat sink

Aluminum expulsion heat sinks serious areas of strength for offering mechanical properties that go with them a fantastic decision for heating the board in an assortment of utilization. Aluminum expulsion heat sinks have a high degree of hardness, which makes them impervious to wear and harm. Here the intensity sink will be presented to high degrees of vibration or shock. Aluminum has a low coefficient of warm development, which implies that it won’t grow or contract fundamentally when presented with temperature changes. Here the intensity sink will be presented to quick temperature changes. Aluminum is a profoundly pliable material, and that implies that it tends to be framed and moulded without breaking or breaking. This considers making perplexing blade plans that amplify surface region and improve heat scattering. Aluminum is an exceptionally machinable material, which implies that it tends to be effortlessly cut, penetrated, and formed to fit the particular prerequisites of intensity of the executives’ application. This takes into account the formation of custom intensity sinks customised to the application’s requirements.

The corrosion resistance of aluminum extrusion heat sink

Aluminum is normally impervious to consumption, implying that it won’t rust or erode when presented with dampness or other destructive conditions. Here the intensity sink will be presented with unforgiving ecological circumstances. The solid, complete mechanical properties of aluminum expulsion heat sinks settle on them an amazing decision for heating the executives’ applications. Their high strength, flexibility, hardness, consumption opposition, warm conductivity, low coefficient of warm development, and machinability add to their viability and flexibility.